HG 50 High-Frequency Welded Pipe Production Line

Brief introduction of ERW high precision tube rolling mill

|

(1)Material Specifications: |

|

|

Standard |

SPHC、SPHT-2、SS 400、SS440、SS490 |

|

Material |

Low carbon steel and low alloy constructional steel |

|

Mechanical properties |

σb≤520Mpa,σs≤365MPa |

|

Strip Width |

39-160mm |

|

Strip Thickness: |

0.5-2.5mm |

|

Inner Diameter of Coils |

Φ508mm |

|

Outer Diameter of Coils |

Φ1300~φ1760mm |

|

Coil Weight |

≤5T |

|

(2)Pipe Specification |

|

|

Pipe Diameter |

Round pipe:φ12.7-50mm Thickness:0.5-2.5mm |

|

Length |

6m |

|

Pipe-cutting Precision |

0-6mm |

|

Forming Speed |

Max 80m/min (max size and thickness cannot up to max speed) |

|

(3)The buyer should self-supply |

|

|

Work shop |

60x6m, H>5m(crane to ground) |

|

Power |

Approx.450KW 380V/50Hz/3phases |

|

Circulation Cooling Water(whole system) |

Flow:20T/h~30 T/h Pool Volume:30m3 |

|

Compressed Air (whole system) |

Flow:5m3/min Pressure: 5-7kg/ cm2 |

|

Cable |

All cable outside of my machine, you buy after machine fix location. |

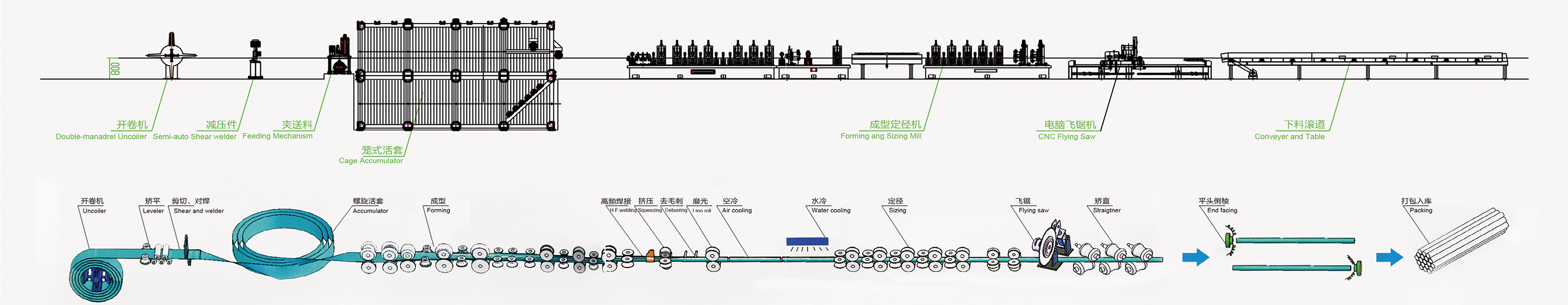

Production Process

Scroll up → Uncoil → Flattening → End Shear & Butt Welding → Accumulator → Forming → High-frequency induction welding→ Removing external burr → Cooling → Sizing → Cutting → Checking & Collecting → Accessing Warehouse

Production flow chart:

ERW Tube Mill Other Model

|

Model |

Diameter Range |

Pipe Thickness |

Molding speed(m/min) |

Motor Power(KW) |

Mechanical |

|

HG20 |

8-20MM |

0.3-1MM |

30-120 |

55 |

7×50 |

|

HG32 |

12-32MM |

0.3-2.0MM |

30-120 |

75 |

7×50 |

|

HG50 |

16-50MM |

0.8-2.5MM |

30-110 |

110 |

7×60 |

|

HG60 |

20-60MM |

0.8-3MM |

30-100 |

132 |

7×65 |

|

HG76 |

12-76MM |

1-3MM |

30-100 |

320 |

8×80 |

|

HG89 |

32-89MM |

1-4MM |

30-80 |

350 |

8×80 |

|

HG114 |

45-114MM |

1.5-5.0MM |

30-60 |

400 |

10×100 |

|

HG165 |

60-165MM |

3-7MM |

30-50 |

600 |

10×110 |

|

HG219 |

114-219MM |

4-8MM |

20-40 |

800 |

12×150 |

|

HG273 |

114-273MM |

4-10MM |

15-30 |

1000 |

18×160 |

|

HG325 |

165-325MM |

4-12MM |

10-30 |

1200 |

18×180 |

|

HG426 |

165-426MM |

4-16MM |

8-25 |

1400 |

18×180 |

|

HG508 |

219-508MM |

4-20MM |

8-20 |

2000 |

21×180 |

Our Services

1.) We will send the engineer for the installation and training your workers how to operate this machine in correct way.

2.) Warranty Team

One year quality guarantee, life guarantee repair. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the cost of the spare parts.

3.) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled engineer for working.

4.) We can also sent the engineer working for you serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5.) We supply the pre-sell service-Design for whole project for stainless steel pipe making/ carbon steel pipe making.

6.) We will be responsible for the loading and shipping.

Inquiry

Add: No.15,Shanqian Road,Economic Development Zone,Hebei,China

Mobile Number: +86 18233100172

Tel: +86-311-83025332

Email: pipemill@sjzztsd.com

Wechat/Whatsapp: +86 18233100172

Services >

冀公网安备 13012902000138号

冀公网安备 13012902000138号