Classification

high frequency pipe making machine

Keywords:

Category:

Details

|

Model Number |

HG76 |

|

Place of Origin |

Hebei, China (Mainland) |

|

Molding speed |

30-100m/min |

|

Pipe diameter |

12-76mm |

|

Pipe Thickness |

1-3mm |

|

Voltage |

380V/220V |

|

Power |

320KW |

|

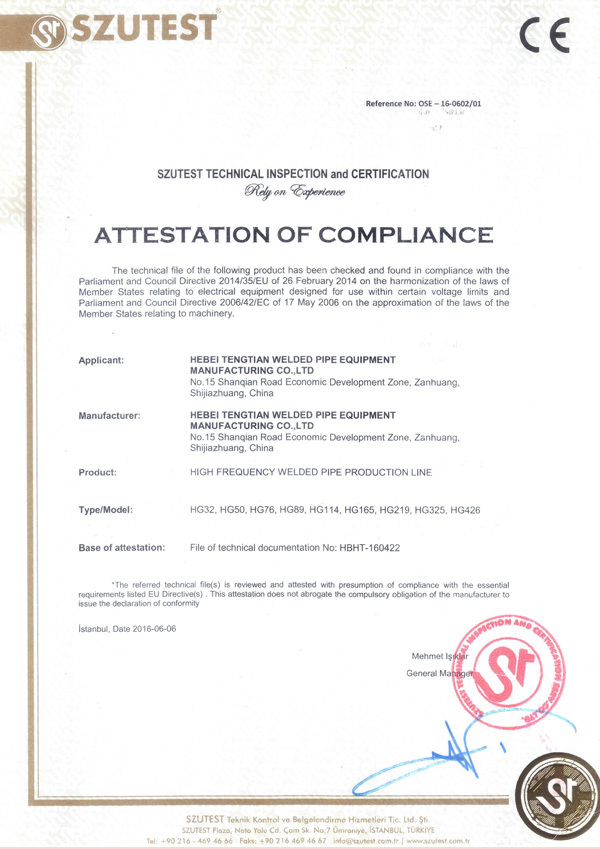

Certification |

ISO9001,CE,BV |

|

Pipe shape |

Rectangle,round,square |

|

Material of Pipe |

Carbon Steel , Stainless Steel and Galvanized Steel |

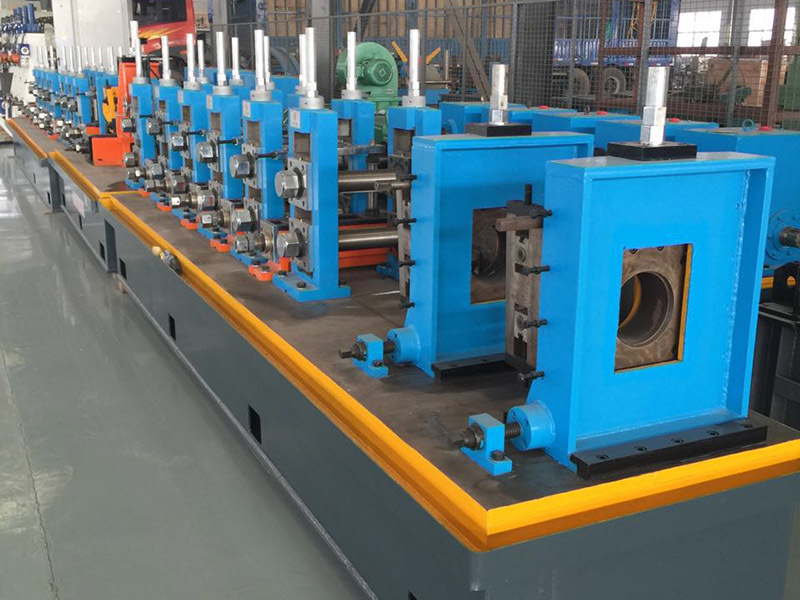

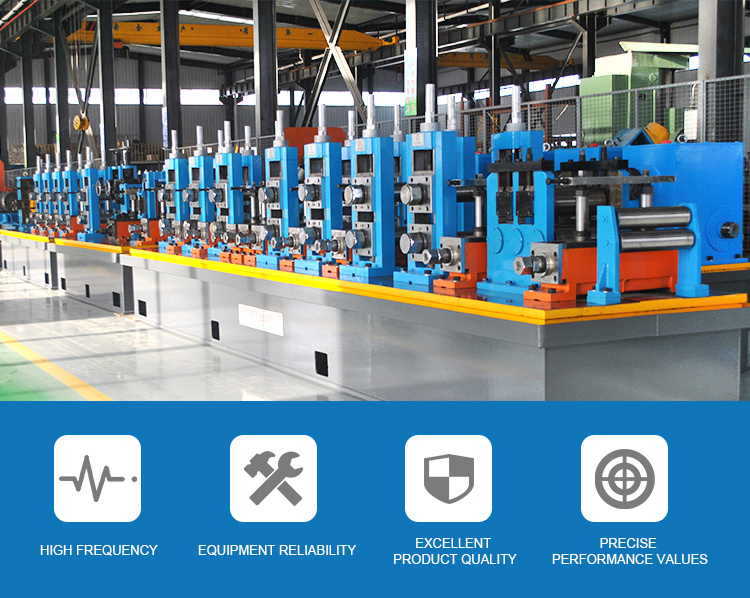

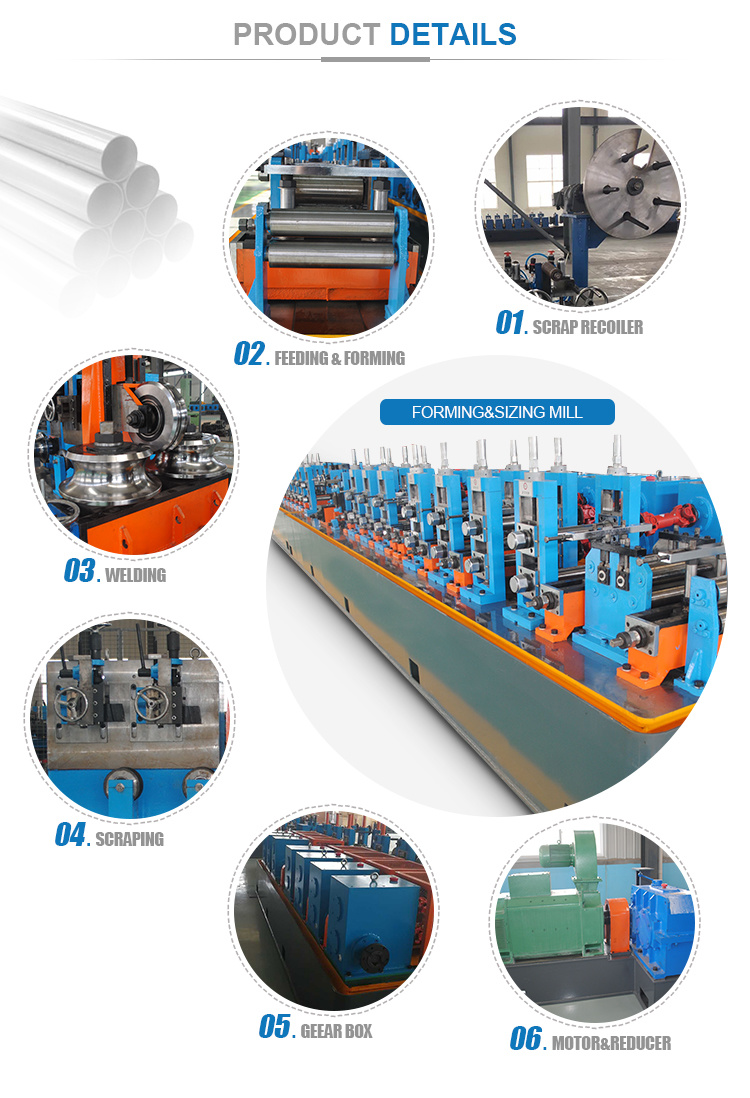

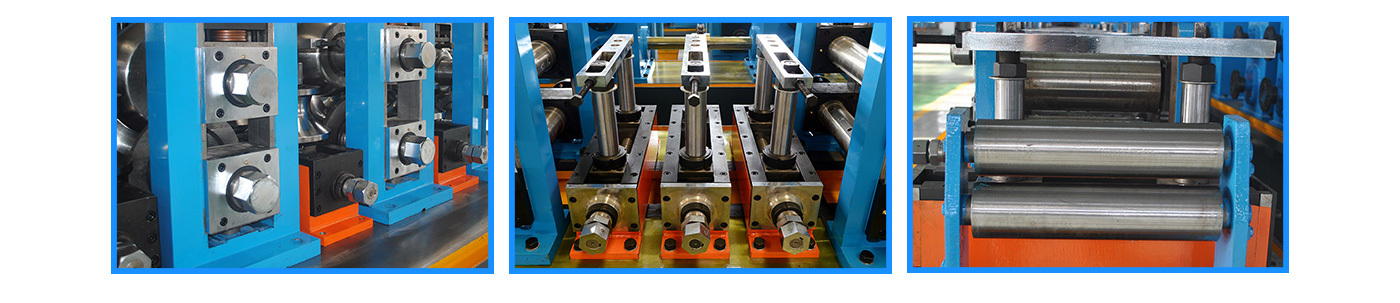

High frequency straight seam welded pipe production line is the specifications of the steel belt feeding unit, through the roll bring curled up into a tube billet steel, and then use the high frequency of proximity effect and skin effect make the strip edge instantaneous heating to welding temperature, and under the action of squeezing roller complete welding, then through water cooling, sizing and straightening as required specifications of the steel pipe. The product line in each units on the basis of digesting and absorbing domestic and foreign similar equipment, combined with China's national conditions, innovative design, convenient operation and maintenance, simple. The machine has high machining quality and assembly precision, and can produce electric welded steel pipe with high precision by adopting reasonable roll pass.

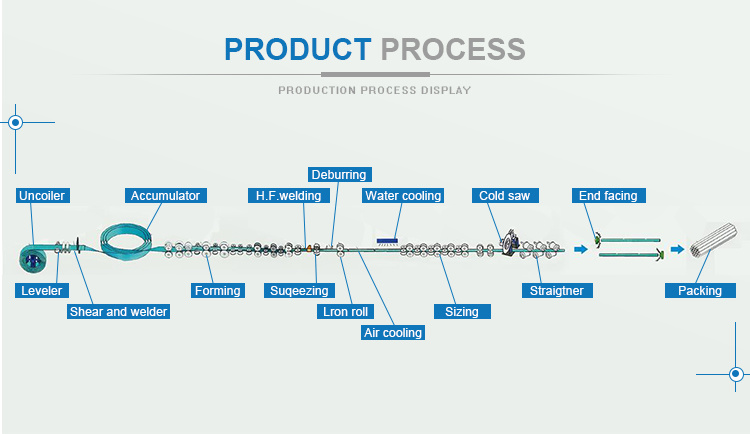

high frequency pipe making machine Production Process

high frequency pipe making machine Scroll up → Uncoil → Flattening → End Shear & Butt Welding → Accumulator → Forming → High-frequency induction welding→ Removing external burr → Cooling → Sizing → Cutting → Checking & Collecting → Accessing Warehouse

high frequency pipe making machine ERW Tube Mill Other Model

|

Model |

Diameter Range |

Pipe Thickness |

Molding speed(m/min) |

Motor Power(KW) |

Mechanical area |

|

HG20 |

8-20MM |

0.3-1MM |

30-120 |

55 |

7×50 |

|

HG32 |

12-32MM |

0.3-2.0MM |

30-120 |

75 |

7×50 |

|

HG50 |

16-50MM |

0.8-2.5MM |

30-110 |

110 |

7×60 |

|

HG60 |

20-60MM |

0.8-3MM |

30-100 |

132 |

7×65 |

|

HG76 |

12-76MM |

1-3MM |

30-100 |

320 |

8×80 |

|

HG89 |

32-89MM |

1-4MM |

30-80 |

350 |

8×80 |

|

HG114 |

45-114MM |

1.5-5.0MM |

30-60 |

400 |

10×100 |

|

HG165 |

60-165MM |

3-7MM |

30-50 |

600 |

10×110 |

|

HG219 |

114-219MM |

4-8MM |

20-40 |

800 |

12×150 |

|

HG273 |

114-273MM |

4-10MM |

15-30 |

1000 |

18×160 |

|

HG325 |

165-325MM |

4-12MM |

10-30 |

1200 |

18×180 |

|

HG426 |

165-426MM |

4-16MM |

8-25 |

1400 |

18×180 |

|

HG508 |

219-508MM |

4-20MM |

8-20 |

2000 |

21×180 |

Our high frequency pipe making machine Services

1.) We will send the engineer for the installation and training your workers how to operate this machine in correct way.

2.) Warranty Team

One year quality guarantee, life guarantee repair. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the cost of the spare parts.

3.) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled engineer for working.

4.) We can also sent the engineer working for you serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5.) We supply the pre-sell service-Design for whole project for stainless steel pipe making/ carbon steel pipe making.

6.) We will be responsible for the loading and shipping .

About us

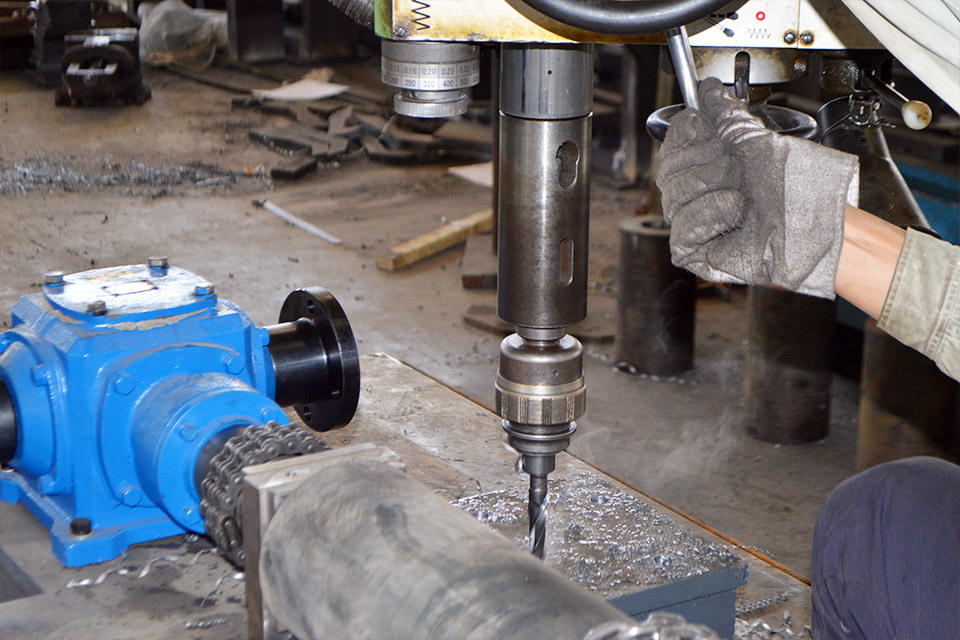

New Full Automation

The company has a strong technical ability, strong business ability, vibrant team. Through the unremitting efforts of all staff, in recent years the company has occupied most of the domestic market, and exported to Korea, Vietnam, Indonesia, South Africa, Kazakhstan and other dozens of countries and regions, from domestic and foreign customers.

Qualification

Our Services

1.) We will send the engineer for the installation and training your workers how to operate this machine in correct way.

2.) Warranty Team

One year quality guarantee, life guarantee repair. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the cost of the spare parts.

3.) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled engineer for working.

4.) We can also sent the engineer working for you serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5.) We supply the pre-sell service-Design for whole project for stainless steel pipe making/ carbon steel pipe making.

6.) We will be responsible for the loading and shipping .

Our customers

Our company specializes in the production of pipe mill, slitting line,cold roll forming,stainless steel pipe mill and other equipment,On the basis of the introduction of the advanced technology of Japan, the company is innovative and the machine are manufactured in strict accordance with the standard of Japan.Advanced configuration,stable quality,excellent performance,with excellent market visibility and reputation,our machine has reached the world's leading level.

Exhibition

Packing and shipping

Our equipment has been exported to dozens of countries and regions such as Egypt, Greece,South Korea,Vietnam,Indonesia,South Africa,etc.,and received favorable comments from domestic and foreign customers.

Contact us

Hebei Tengtian Welded Pipe Equipment Manufacturing Co., Ltd.

Add:No.15,Shanqian Road,Economic Development Zone,Hebei,China

Mobile Number:+86 18233100172

Tel:+86-311-83025332

Email:pipemill@sjzztsd.com

Previous:

Product inquiry

Related products